Thermal Mass Insulation:

Because Your Walls Deserve a Blanket Too

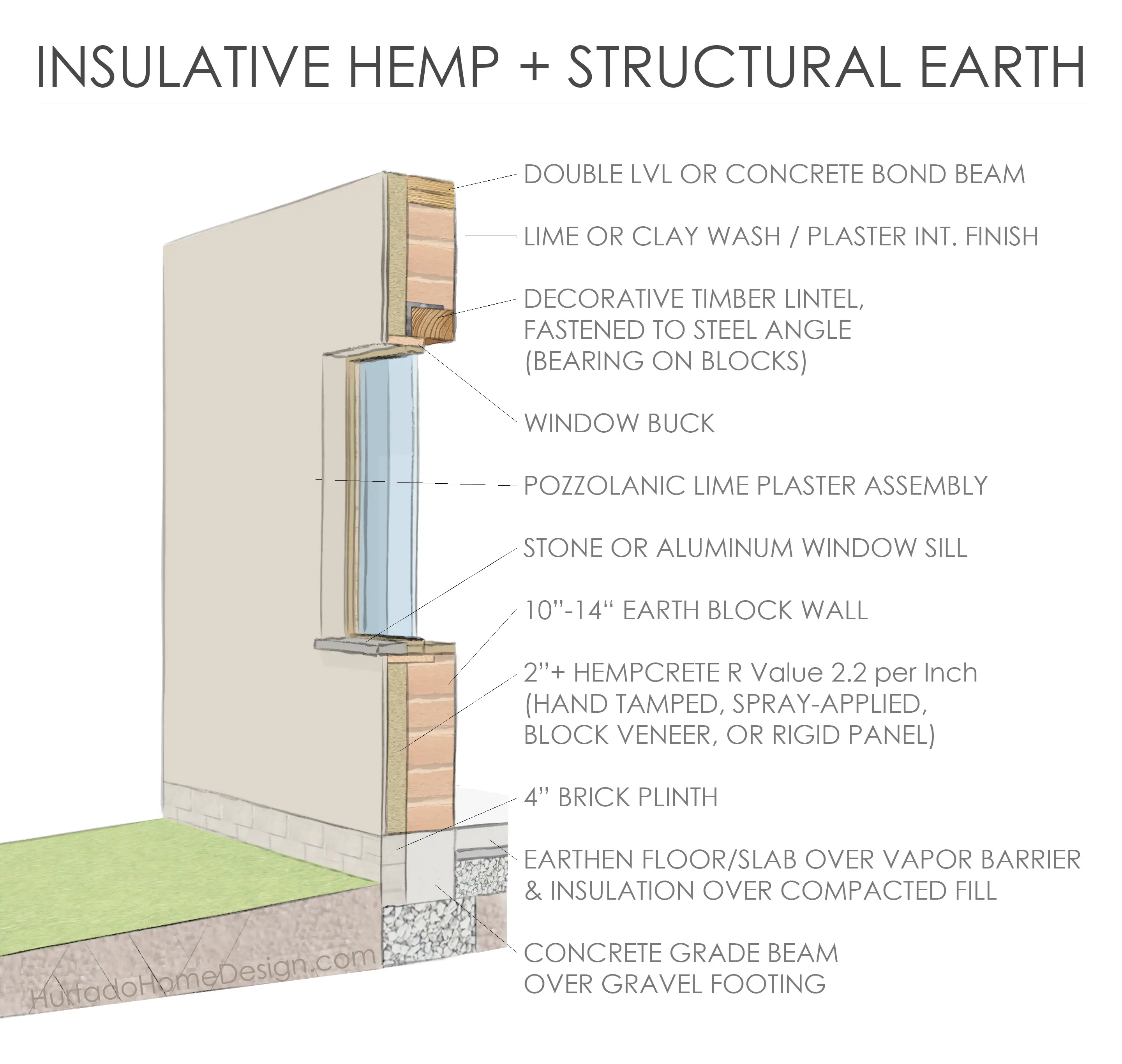

Thermal mass insulation is unique when it comes to earth block walls, working differently than standard above-grade walls. Instead of just blocking heat, the thermal mass absorbs and releases it, helping to keep indoor temperatures stable and comfortable. This natural process reduces energy use and improves overall efficiency, while adding insulation ensures the design meets specific climate needs for optimal comfort.

Does thermal mass always need insulation to be effective?

Does thermal mass always need insulation to be effective?

Uninsulated thermal mass works best in climates with significant day-to-night temperature swings, absorbing heat during the day and releasing it at night. However, in many locations, there are times of the year when temperatures don't cool down enough at night, or where direct sunlight is blocked by cloud cover during the day. That’s when adding insulation can help keep interior temps more balanced. It comes down to your local climate and what you need for your home.

Question: Can thermal mass walls overheat spaces?

Question: Can thermal mass walls overheat spaces?

Yes, certain conditions can contribute to overheating if thermal mass is not properly managed.

To prevent overheating, it's important to use shading, ventilation, and insulation to manage heat absorption effectively.

- Inadequate Ventilation: Poor air circulation, whether due to insufficient passive ventilation or a lack of mechanical systems, can trap heat and humidity, making the space uncomfortable.

- Incorrect Placement: Thermal mass walls in areas with too much direct sunlight, without shading, may overheat.

- Inadequate Insulation: Without insulation, thermal mass is exposed to outside temperatures. In hot weather, it can absorb too much heat, and in cold weather, it may bring in the chill, making indoor temperature regulation harder.

Innovative Thermal Mass Insulation Strategies

for Earth Block Walls

Insulating compressed earth block walls also allows for creative, innovative strategies that truly set them apart from traditional wall systems. Keep reading to discover more about the unique strategies that make insulated earth block walls both efficient and versatile.

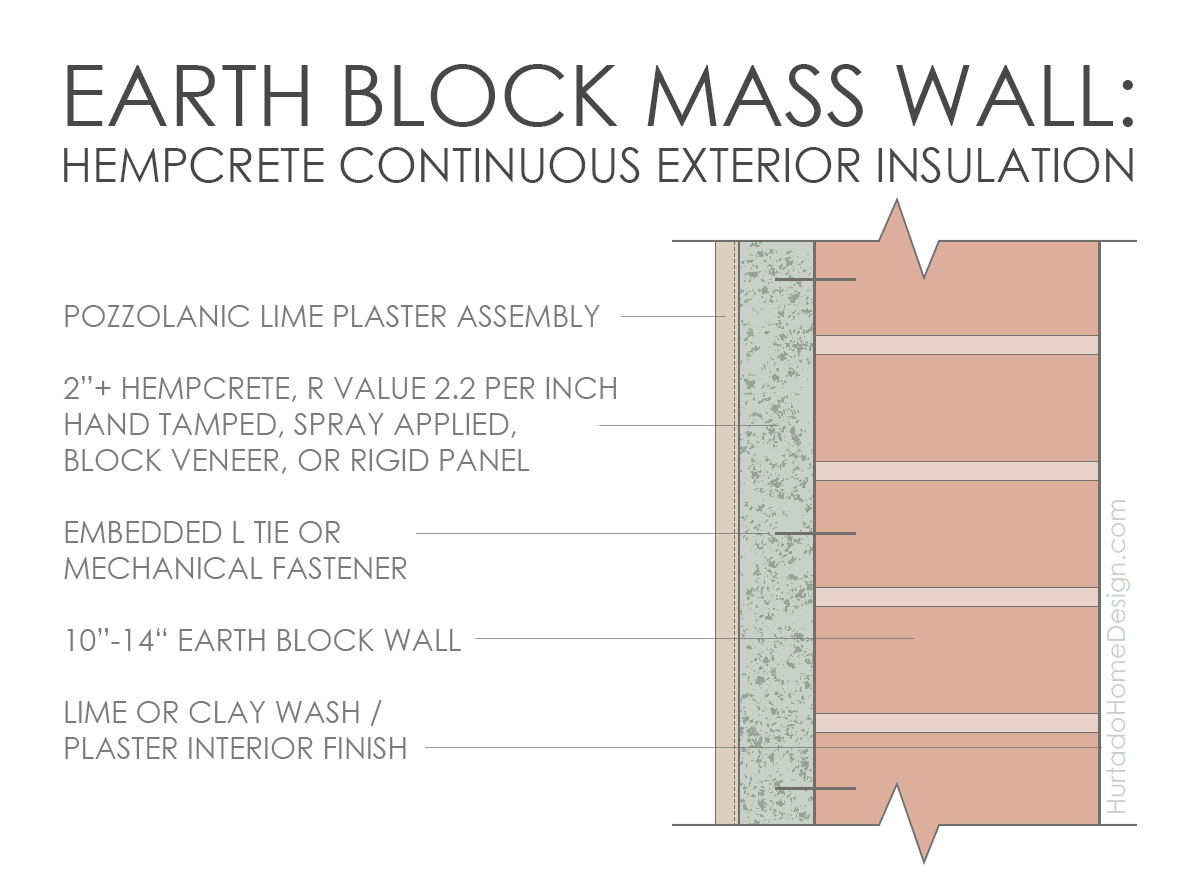

Hempcrete as Continuous Exterior Insulation

- Hempcrete enhances building durability by insulating, reducing thermal bridging, and allowing walls to breathe.

- Promotes sustainability by using renewable materials and contributing to carbon sequestration over its life cycle.

- Hempcrete is not a load-bearing material and typically requires a structural frame, making it suitable as an insulating layer in combination with other systems.

- Its fire-resistant properties and ability to improve indoor air quality further enhance its appeal as an eco-friendly building material.

Thermal Performance

- Acts as a thermal barrier, reducing heat transfer through walls.

- Helps prevent thermal bridging, which occurs when heat escapes through structural elements like studs or beams, improving energy efficiency.

Breathability and Moisture Regulation

- Allows water vapor to pass through, preventing trapped moisture in the wall assembly.

- Reduces risks of mold growth, structural decay, and decreased insulation effectiveness, promoting a healthier indoor environment.

Natural Composition

- Made from a mix of hemp shiv, lime-based binder, and water.

- Non-toxic and environmentally friendly: Hemp is a renewable resource that absorbs CO₂ as it grows. Lime has a lower embodied energy compared to Portland cement.

Application Methods for Hempcrete

Spray-applied: Hempcrete can be sprayed directly onto walls using specialized equipment, creating a seamless, continuous layer of insulation.

- Faster application for large projects compared to hand-packing.

- Ensures consistent coverage, reducing gaps that could compromise insulation performance.

- Ideal for retrofits or when creating a protective outer layer on existing walls.

- Requires skilled labor and specific machinery, making it less DIY-friendly.

Hand-packed: This traditional method involves manually mixing and applying hempcrete, then tamping it into place within a formwork.

- Suitable for small-scale projects or areas that are difficult to access with machinery.

- Allows for greater control over material placement, making it ideal for intricate designs or repairs.

- Can be a cost-effective solution for DIY builders.

- Time-consuming and labor-intensive, making it impractical for larger projects.

Prefabricated Blocks: Hempcrete is manufactured into blocks that can be stacked like masonry units, often used as a veneer over structural walls.

- Quick and easy to install, especially for non-load-bearing applications.

- Offers uniformity in insulation thickness and thermal performance.

- Suitable for projects requiring precise dimensions and standardized materials.

- Prefabricated blocks may be more expensive upfront and require proper handling during transport to avoid damage.

Hemp Panels: Rigid panels made from hempcrete provide an alternative to spray-applied or hand-packed methods, offering uniformity and ease of installation.

- Lightweight and easy to handle, making installation faster and less labor-intensive.

- Ideal for projects where time is a constraint, such as modular construction or prefabrication.

- Can be integrated into wall systems as exterior or interior insulation.

- Limited flexibility in shape and size may require adjustments during installation.

The choice of application method depends on:

- Project Scale: Large-scale projects may benefit from spray application or prefabricated panels, while hand-packing is better for smaller areas or custom designs.

- Budget: Hand-packing can save costs on equipment, while prefabricated blocks or panels might have higher material costs but save on labor.

- Time Constraints: Prefabricated blocks and panels are the quickest options, whereas hand-packing is more time-intensive.

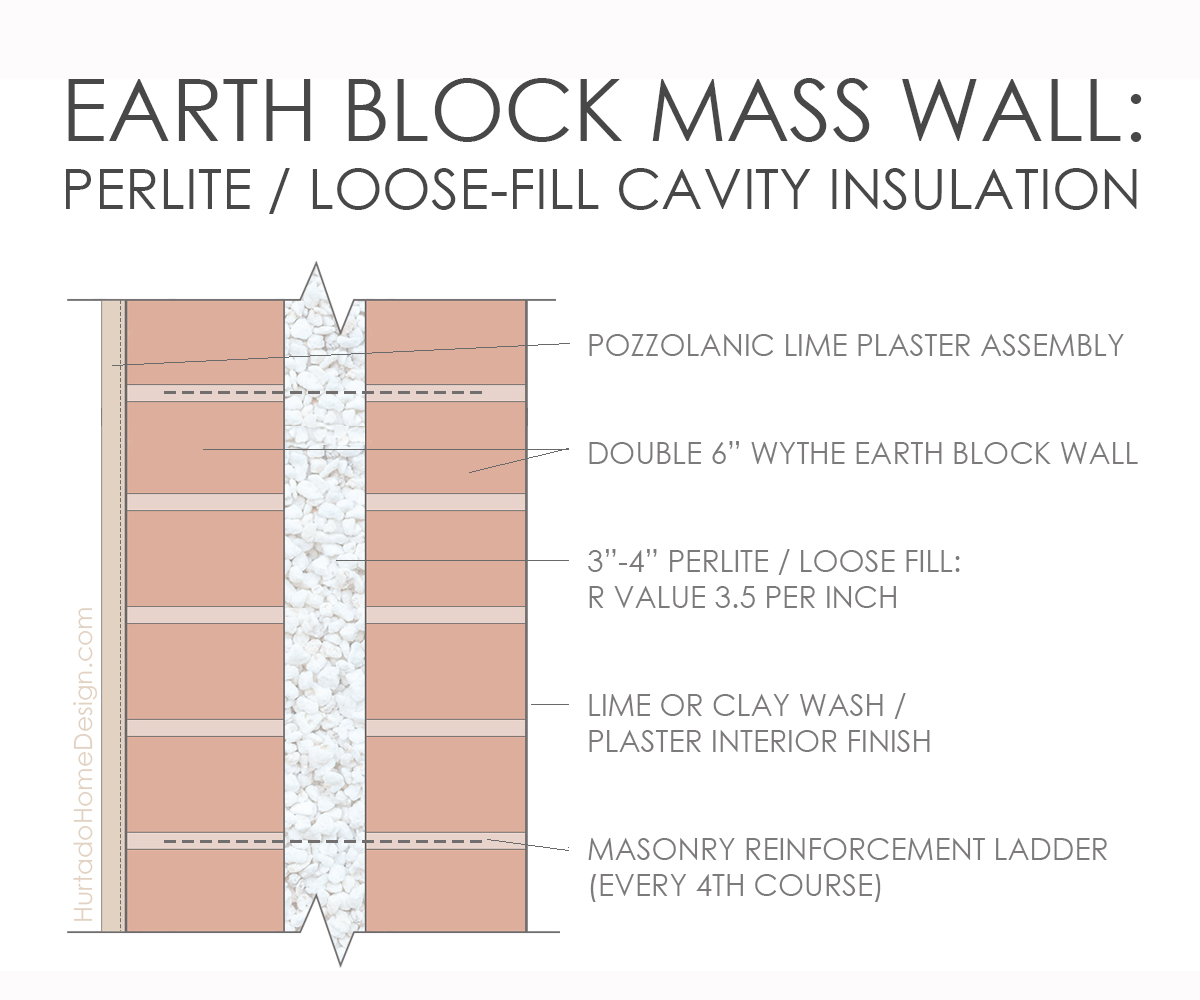

Cavity Insulation Options for Double Wythe Earth Block Walls

Each of the following cavity thermal mass insulation options has unique advantages, allowing for a customized approach depending on project requirements and client preference.

Using cavity insulation in a double wythe earth block wall can significantly improve thermal performance.

Using cavity insulation in a double wythe earth block wall can significantly improve thermal performance.Perlite Insulation

- Thermal Performance: Excellent insulating properties due to its air-filled structure, helping maintain stable indoor temperatures.Reduces thermal bridging, minimizing heat transfer through the wall.

- Non-Toxic and Eco-Friendly: Natural volcanic glass expanded by heating, making it a sustainable choice. Contains no harmful chemicals.

- Fire Resistance: Non-combustible, enhancing the fire resistance of the wall assembly.

- Moisture Management: Can absorb some moisture without losing insulating properties, making it suitable for walls exposed to intermittent moisture.

- Durability and Lightweight: Does not degrade or settle over time, maintaining consistent performance. Lightweight and easy to handle during installation.

- Perlite is an excellent choice for filling cavities in masonry walls because it flows easily into crevices, ensuring a consistent and complete fill.

Loose-fill cellulose and sheep’s wool are earth-friendly insulation options that align with sustainable building practices, though they may require more careful installation compared to perlite:

Loose Fill Cellulose Insulation

- Thermal and Acoustic Performance: High insulating value due to its dense nature, which reduces heat loss and enhances soundproofing. Effective at minimizing air leakage within the cavity.

- Eco-Friendly and Recyclable: Made from recycled paper products, making it a sustainable insulation choice. Non-toxic and treated with borates for pest and fire resistance.

- Moisture Absorption: Can absorb and release moisture, helping regulate humidity levels.

- Fire and Pest Resistance: Treated with fire-retardant chemicals to enhance safety. Resists mold, mildew, and pests due to the borate treatment.

Blown-in Sheep's Wool Insulation

- Natural and Non-Toxic: 100% natural, renewable, and biodegradable, making it an environmentally friendly insulation option. Free from harmful chemicals.

- Superior Moisture Management: Naturally hygroscopic, sheep’s wool can absorb and release moisture without losing insulating capabilities.

- Thermal and Acoustic Insulation: Offers excellent thermal resistance and sound absorption. The natural crimp of the wool fibers traps air, enhancing insulation effectiveness.

- Fire Safety and Durability: Naturally fire-resistant, as wool has a high ignition temperature. Durable and long-lasting, with fibers that maintain their structure over time.

Combining thermal mass insulation with

passive design elements like shading or proper window placement can

further enhance comfort and sustainability.